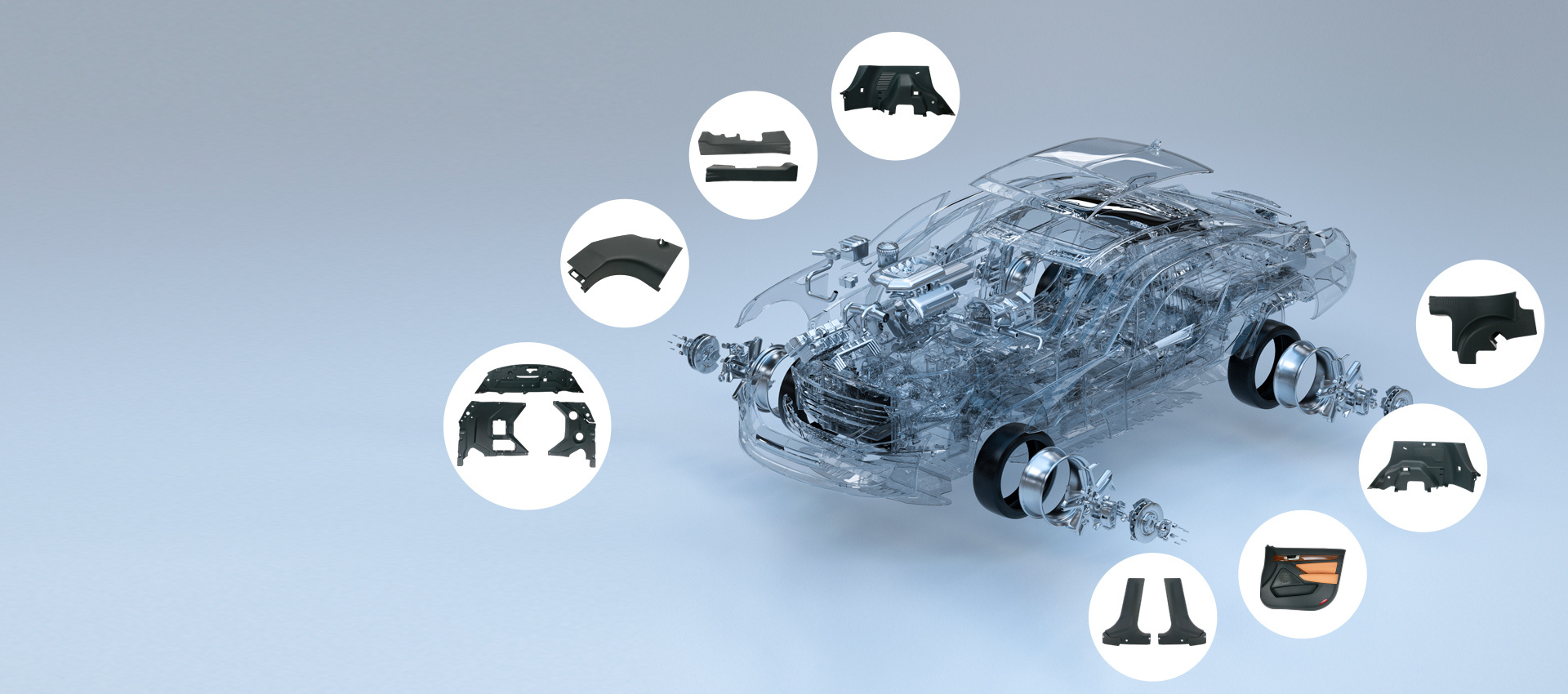

Product Category

Committed to the research and development and application of plastic and rubber products in the field of vehicles and electronics

Jiangmen Shenqiang Plastic Machinery Co., Ltd.

Jiangmen Shenqiang Plastic Machinery Co., Ltd. was established in 2002 and is located at No. 195, Jinxing Road, High-tech Industrial Park, Jiangmen City. It is a professional enterprise mainly producing auto parts, injection molding parts, a complete set of plastic covering parts and rubber parts for motorcycles, lamps and massagers. The company has invested more than 200 million yuan, covers an area of nearly 100 mu, and has a total of several hundred people. Among them, various management and technical personnel, research and development personnel, and quality management personnel have been introduced. The company aims to build a first-class enterprise.

Founded

Floor area

Workers

Honor Certificate

Quality management system, environmental management system, pollutant discharge permit, safety production standardization

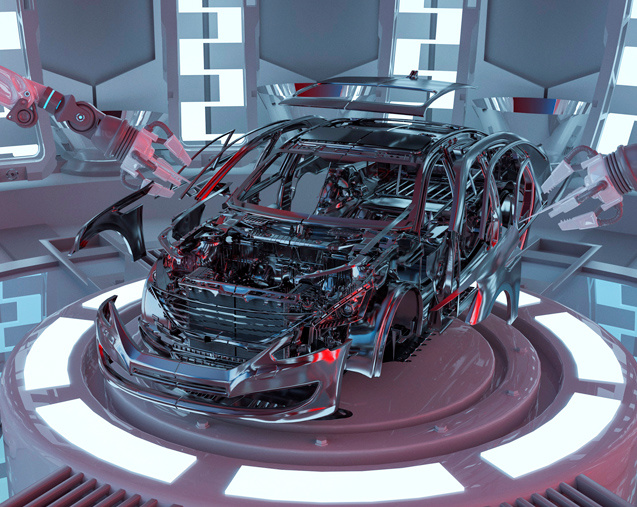

Manufacturing Capacity

The company has modern technology and equipment, 86 injection molding machines, 6 sets above 1000T, and the maximum is 1850T, all equipped with robots to ensure that the products meet the requirements of customers from quality to output.

Plant Equipment

The company invested more than 200 million yuan and covers an area of nearly 7 acres

News

Founded in 2003, it is located at No. 195, Jinxing Road, Jianghai District, Jiangmen City, Guangdong Province, adjacent to Hong Kong and Macao, and close to Guangzhou, with convenient transportation. The company invests more than 200 million yuan, covers an area of 57334 square meters, has more than 500 management, technical personnel and workers, and has strong independent development ability. It has a full set of advanced injection molding machines, including 80 sets of Mark Haitian 80T-1300T, 2 assembly lines for lamps, and 6 painting lines. 15 rubber molding machines. The company has passed the ISO/TS16,949:2002 quality system certification, the "AAA" quality credit rating certificate issued by the China Product Quality Association, and has more than 100 patents. Now Jiangmen Company has become a supporting company of Dongfeng Nissan, providing a variety of interior and exterior trims for passenger cars, mainly including Bluebird Supreme (part: electroplating trim strip of the rear trunk, interior trim strip of the trunk, left and right side covers, MKSK-A, MASK-B rear license plate, etc.); Sunshine (part: electroplating decorative strip of rear boot, rear license plate, etc.); Yida (Qida) (part: control panel, brake trim cover, rear cup holder, central armrest, glove box, skeleton, etc.). Shenqiang Company adheres to the business tenet of "quality first, reputation first", pursues the entrepreneurial spirit of "being realistic, rigorous, innovative and enterprising", wholeheartedly serves new and old customers, and sincerely welcomes customers at home and abroad to call and write to the company to discuss business and investment cooperation matters.

Founded in 2003, it is located at No. 195, Jinxing Road, Jianghai District, Jiangmen City, Guangdong Province, adjacent to Hong Kong and Macao, and close to Guangzhou, with convenient transportation. The company invests more than 200 million yuan, covers an area of 57334 square meters, has more than 500 management, technical personnel and workers, and has strong independent development ability. It has a full set of advanced injection molding machines, including 80 sets of Mark Haitian 80T-1300T, 2 assembly lines for lamps, and 6 painting lines. 15 rubber molding machines. The company has passed the ISO/TS16,949:2002 quality system certification, the "AAA" quality credit rating certificate issued by the China Product Quality Association, and has more than 100 patents.

09-16

In 2014, the company began its strategic transformation, focusing on increasing investment in the automotive industry, general machinery industry and electronics industry. After two years of design, certification, manufacturing capacity assessment and review of OEMs, the company began to harvest investment results in the automotive industry in 2016. It is estimated that in 2016, the sales revenue of automobile products and general machinery products will increase by 120 million yuan, the profit will increase by more than 8 million yuan, the sales revenue of other products will increase by about 30 million yuan, and the profit will increase by more than 2.5 million yuan. As the products become more and more mature, they will have more and more experience in the automotive products and electronic products industry, and the market sales will also increase year by year. According to the communication with the OEMs and the market forecast, the growth rate will be no less than 20% every year from 2016.

Developed countries in the plastic machinery industry, such as Germany, the United States and Japan, have occupied an important position in the world plastic machinery industry with their advantages in precision, large and high-end plastic machinery products and talents; At the same time, relying on years of plastic machinery manufacturing experience and technology accumulation, and relying on the huge domestic and international consumer market, a number of large-scale plastic machinery enterprises have emerged to participate in global competition. At present, countries in Southeast Asia, Central and Western Asia, and Central and Eastern Europe are all important export places of China's plastic machinery products, and they have distinctive characteristics of complementary industrial advantages, which promote the production capacity cooperation between China's plastic machinery and the polymer composite processing industries in the world, and provide a broad market space.

The automobile industry has always been a pillar industry of the country, especially new energy vehicles. The country has issued a series of policies to vigorously support new energy vehicles.

Auto parts industry: China produces more than 20 million cars annually, and the cost of interior decoration of each car is about 8000 yuan, only the door panel is about 1300 yuan. According to the calculation of the door panel, the annual sales market volume will reach 26 billion yuan. If the market share is 1%, the annual sales will reach 260 million yuan.

Partner

The company's products have spread all over the country and exported to the United States, Brazil, Argentina, Germany, Italy, Russia, Turkey, Japan, South Korea, Vietnam, Cambodia, Egypt, Nigeria, South Africa and other countries and regions, and are well received by customers .

Jiangmen Shenqiang Plastic Machinery Co., Ltd. is a professional enterprise mainly engaged in the production of auto parts, injection molding parts, complete sets of plastic cover parts and rubber parts for motorcycles, lamps and massagers.

Jiangmen Shenqiang Plastic Machinery Co., Ltd.

Add: No. 195 Jinxing Road, Jiangmen High-tech Industrial Park, Guangdong, China

Mobile: 13750322695 (Ms. Wang)

Phone: 0750-3866927

Domestic Trade Business Department Mobile: 13725907142

Email: minzhao@jmshenqiang.com

Foreign Trade Business Department Mobile: 13680515954

Email: jmsqsales@jmshenqiang.com

Web:www.jmshenqiang.com